2017-12-11

The organic fertilizer production line is commonly used to process different fermented organic substance into bio-organic fertilizer. It adopts one-step molding technology. Animal manure and agricultural waste are recycled as the main raw materials, thus manure or dung waste is not only creating economic benefits for the enterprise, but also making a great contribution to environmental projects for mankind.

The raw material of bio-organic fertilizer:

1. Agricultural waste: straw, rice bran, etc.

2. Animal waste: chicken manure, pig, cattle and sheep manure, etc.

3. Industrial waste: vinasse, sugar residue, etc.

4. Household waste: kitchen waste, vegetable market and slaughterhouse waste, etc.

5. Municipal sludge: river silt, sewage sludge, etc.

After safety disposal and fermentation, these materials are made into organic fertilizer. Thus, organic fertilizer containing a variety of organic acids, peptides, and rich nutrients including nitrogen, phosphorus and potassium. Not only provide comprehensive nutrition for crops, also with long fertilizer effect, which can Increase and update the soil organic matter and promote microbial breeding, improve soil physical and chemical properties and biological activity.

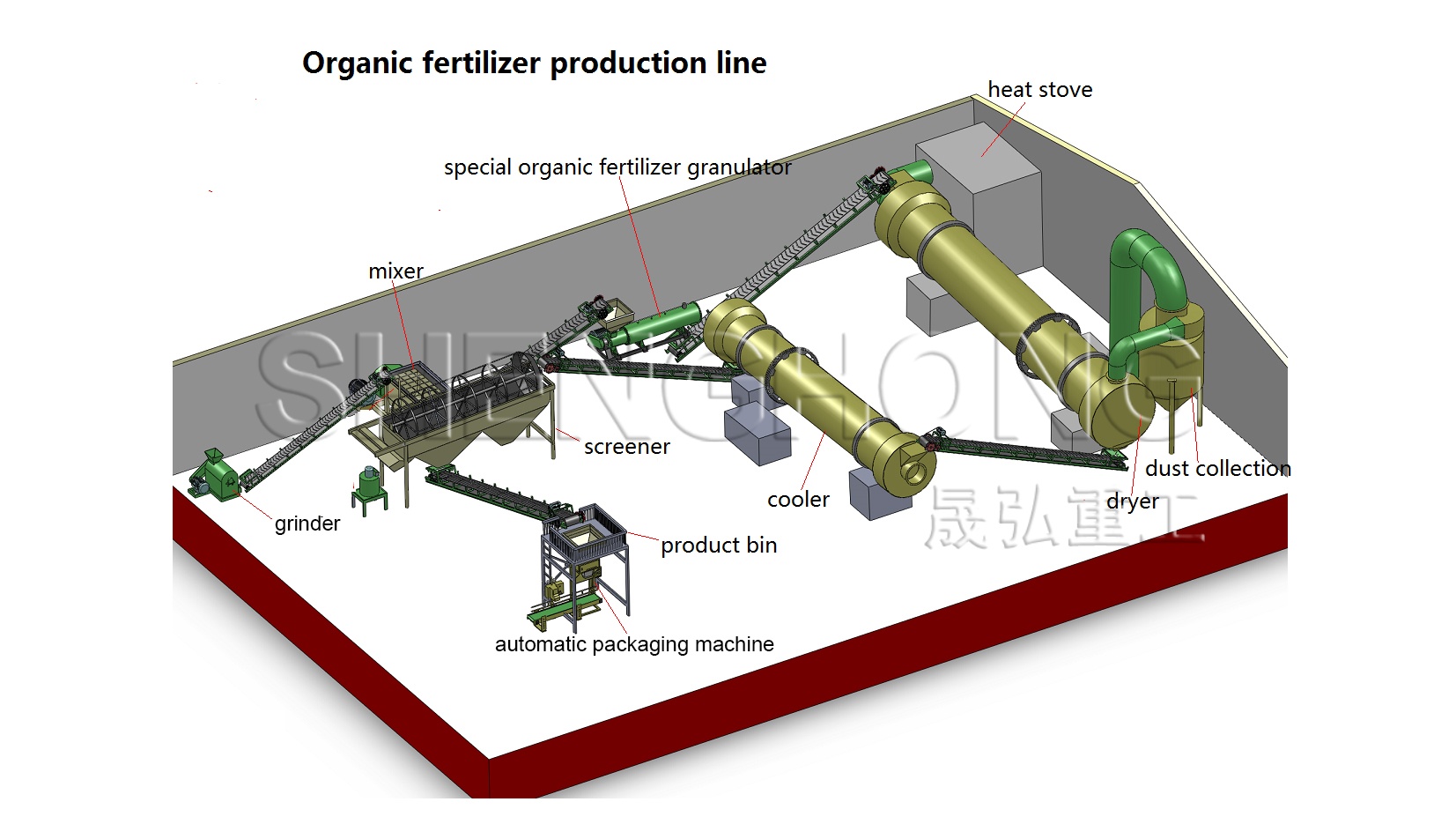

Main parts of bio-organic fertilizer production line:

1. Turner Machine

2. Half-wet Material Crusher

3. Mixer

4. Organic Fertilizer Granulator

5. Drying Machine

6. Cooling Machine

7. Drum Screening Machine

8. Belt Conveyor

9. Automatic Packaging Machine

This organic fertilizer production line is located in shangdong province, China. and production capacity 5-6 tons per hour. welcome to visit our factory and the working site if you are interested.

More questions, feel free to contact us!

Zhengzhou Shenghong Heavy Industry Technology Co.,Ltd.

Website:www.tcfertilizermachine.com

Email: [email protected]